Join us in meeting Dan Schoenberg, one of the owners of The Sewing Machine Shop located in the greater bay area of California!

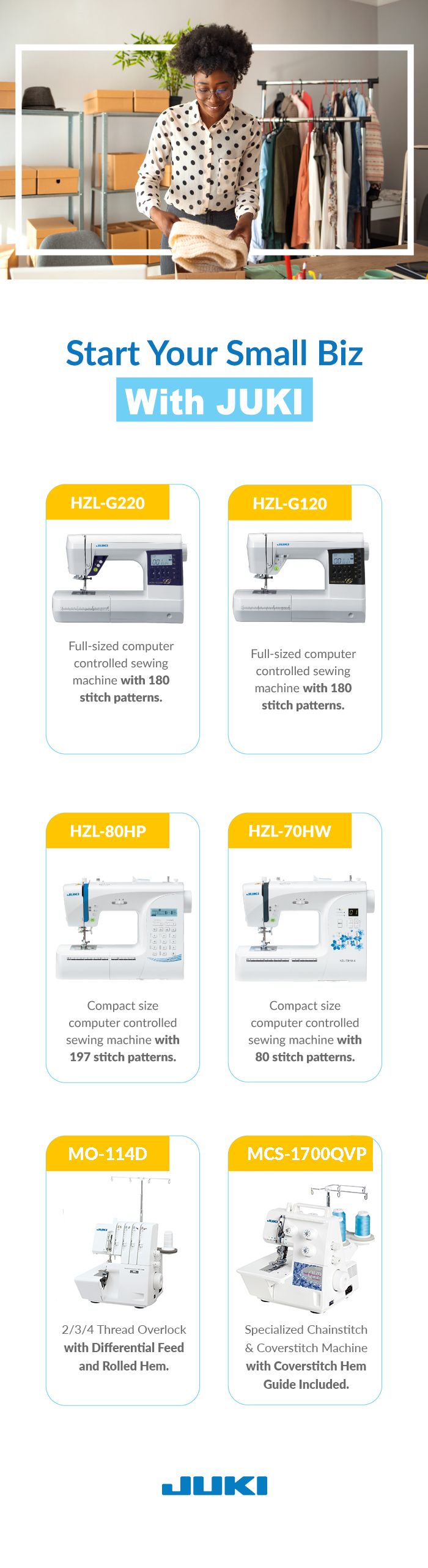

Offering creators like you the full JUKI Line, sewing accessories, notions, and more, The Sewing Machine Shop is ready to help you find the right machine for your next dream project.

Follow along below for the transcript version of our interview with Dan Schoenberg, one of the owners of The Sewing Machine Shop.

Hi, my name is Daniel Schoenberg I’m the owner of the sewing machine shop here in Walnut Creek California. We’ve been in business for 35 years and we specialize in the sales and service of household and Industrial sewing machines. We carry a lot of related accessories and supplies like thread and needles presser feet scissors etc. and yeah that’s about it. That’s what we do; we don’t do vacuum cleaners, we don’t do alternative appliances, we’re just sewing machines only.

What Inspired You To Open The Sewing Machine Shop?

I actually started out of college; my older brother was a commercial sewing machine technician and he wanted to start a shop when I finished College. He gave me a job offer and the rest is history. We started in 1987 and have been growing ever since.

Why Do Customers Love Visiting The Sewing Machine Shop?

We have a very good reputation now built up over many years. We carry a variety of sewing machines, different brands, models, types; so everyone can come and sew on these machines and compare models with a fairly unbiased view of what we like.

What Machines Can A Customer Find At Your Shop?

When customers come here, first they’ll see that big selection of machines. We carry four different brands, and they can get machines from as little as 200 going all the way up to our top-of-the-line machines in excess of fifteen thousand dollars. We carry a lot of specialty machines; we carry long arm quilting machines like you see here on the right, and we carry embroidery machines, multi-needle, for commercial and semi-commercial use. We have a very very good staff here that are all accomplished sewers themselves so when you get a demonstration on machines you’ll be able to get a professional opinion and you’ll be able to ask all your questions that you have, all your concerns should be answered very honestly and straightforward.

What Are The Benefits Of Being A Customer?

So once a person purchases a machine from us they’ll get great service beyond the sale. We have extensive classes, usage classes to learn how to use the machine, all the way up to more advanced classes to learn how to create garments, create quilts. We have three full-time technicians here so we do a lot of servicing and repair work, including any warranty work that our customers might need, and customers can just drop in sometimes anytime for minor things like fixing a needle threader. We can diagnose the machine in front of them many times, we can get them going right away, we don’t need them to leave their machine if it’s something simple that we can fix on the spot and many times we don’t even charge any money for that

Why Did You Start Carrying JUKI Machines?

Yeah, we started carrying JUKI machines many years ago. We started even before they introduced a full domestic multi-stitch machine. So the machines we focused on with JUKI were the machines that bridge the gap between household sewing and Commercial sewing. Our most popular JUKI machine is their TL series, which they’ve had for many years, and that is a semi-industrial straight stitch only machine that can sew quite high speeds up to 15 – 1600 stitches per minute. It can take all standard, common industrial sewing machine accessories and it’s a huge seller among not only our quilting Quilters who like speed and a larger throat area, but our garment sewers, and tailors, and dressmakers, and designers as well.

What Makes The Sewing Machine Shop Unique?

I think what makes The Sewing Machine Shop unique is our staff and our people and the vast knowledge that we combine as a group. So between me and the rest of our technicians from the technical side, we’re talking about about a 100 years combined of experience working on machines, and our staff we have another, I would say another 100 years of combined sewing experience. Whether it’s quilting or garment making, or embroidery which is a big aspect of what we do, so I think the selection of the machines having five different brands that you can compare side by side combined with our staff with a vast experience is what sets us apart from other sewing machine dealers.

Having a place where you can actually try the machines before you buy the machines in a no-pressure environment is a very important thing, especially now with the internet and being able to buy so many things online and not getting to touch it, to try it, to listen to the sound of the machine, to ask all your questions in real time; I think that is what I would like to express my customers.

Come into the shop and just take a look around. Talk to our staff, just browse, sew on the machines if you want; if you don’t want to that’s okay too, see what supplies and accessories and notions we have here so the next time you’re in need of anything that has to do with sewing or sewing machines you’ll know what we offer.

How Can We Contact The Sewing Machine Shop?

thanks for listening to this video and I just invite everyone to come on down to the sewing machine shop the best way to really stay in touch with us is to go to our website sewing machine shop.com and you can sign up for our newsletter and our email on our email list um you can also follow us on Facebook but I think we’re sending out weekly informational articles promotions future classes and events so uh go to sewing machineshop.com sign up for our email list and you’ll be able to stay in touch with us

To learn more about The Sewing Machine Shop, visit their website here! Thank you for joining us today in getting to know RDan Schoenberg, one of the owners of The Sewing Machine Shop. We hope you get a chance to visit the next time you’re in the area!