In a world where environmental consciousness is becoming increasingly important, we must adopt eco-friendly habits in every aspect of our lives, including our beloved hobbies! Whether you’re a seasoned sewist or a quilting novice, embracing sustainable techniques can make a significant difference. Let’s explore how to make your sewing and quilting practices more eco-friendly.

Eco-Friendly and Sustainable Sewing Techniques

Adopting sustainable sewing techniques is about more than just choosing the suitable fabrics. It involves a holistic approach to your sewing process, from your equipment to how you plan and execute your projects. By integrating these eco-friendly practices, you can significantly reduce your environmental footprint!

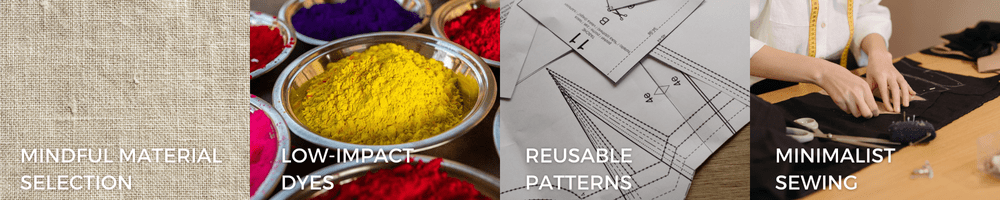

- Mindful Material Selection:

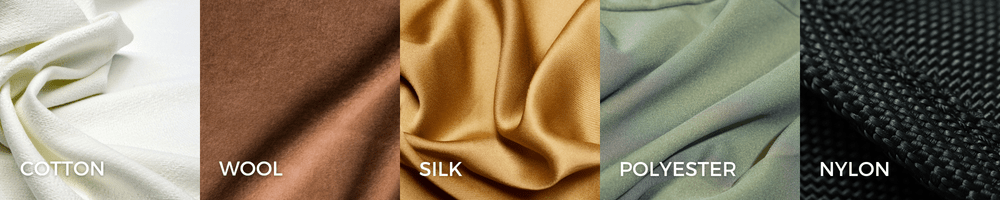

- Choose natural fibers like organic cotton, linen, and wool, which are biodegradable and have a lower environmental impact than synthetic fabrics.

- Look for certifications like GOTS (Global Organic Textile Standard) to ensure the fabric is produced sustainably and adheres to strict environmental and social criteria.

- Low-Impact Dyes:

- Opt for fabrics dyed with low-impact or natural dyes. These dyes use less water, produce less waste, and contain fewer harmful chemicals, making them better for the environment and your health.

- Support companies that use environmentally friendly dyeing processes and are transparent about their production methods.

- Reusable Patterns:

- Invest in reusable, high-quality patterns, or create your own to reduce waste and save money over time! Digital patterns can also be a sustainable choice as they eliminate the need for physical packaging and shipping.

- Join online communities to share and swap patterns with fellow sewists.

- Minimalist Sewing:

- Embrace minimalist sewing by focusing on quality over quantity. Create timeless, durable, versatile pieces, reducing the need for constant replacements.

- Plan your projects carefully to ensure you only purchase the necessary materials, avoiding excess consumption.

Sourcing Sustainable Materials

Finding sustainable materials is crucial for reducing the environmental impact of your sewing projects. By sourcing responsibly, you can support ethical practices and contribute to a more sustainable textile industry!

- Thrift and Vintage Stores:

- Explore thrift stores, vintage shops, and estate sales to find unique and affordable fabrics. Repurposing old clothing and linens into new projects saves money and reduces waste.

- Get creative with your finds, turning them into one-of-a-kind pieces with a story to tell!

- Eco-Friendly Fabric Stores:

- Support fabric stores that specialize in sustainable and organic materials! Many online retailers offer a wide selection of eco-friendly fabrics, from organic cotton to recycled polyester.

- Look for stores that provide transparency about their sourcing and production processes.

- Local Artisans and Producers:

- Purchase materials from local artisans and producers to reduce carbon footprints associated with shipping and support local economies.

- Attend local craft fairs and markets to discover unique, handcrafted materials that add a personal touch to your projects.

- Natural and Recycled Fibers:

- Look for fabrics made from recycled fibers or those blended with natural materials. Brands like Econyl and Repreve offer fabrics made from recycled plastics, reducing waste and promoting circular economy practices.

- Consider alternative fibers like hemp, bamboo, and Tencel, known for their sustainability and durability.

Reducing Sewing Waste

Reducing waste is a crucial aspect of sustainable sewing! By being mindful of how we use and dispose of materials, we can minimize our environmental impact and maximize our resources.

- Use Your Scraps:

- Save fabric scraps for smaller projects, patchwork, or quilting. Scraps can also be used for stuffing pillows, creating unique fabric art, or even making small accessories like scrunchies and keychains.

- Organize your scraps by size and color to make them easier to use in future projects.

- Zero-Waste Patterns:

- Explore zero-waste patterns designed to use every bit of fabric with minimal leftover waste. These patterns often feature innovative cutting techniques and clever designs that maximize fabric usage.

- Experiment with creating your own zero-waste patterns, challenging yourself to think creatively about fabric layout!

- Efficient Cutting Techniques:

- Plan your projects carefully to maximize fabric usage. Use efficient cutting techniques to reduce waste, such as nesting smaller pattern pieces within larger ones and cutting on the fold.

- Invest in a good-quality rotary cutter and mat to achieve precise cuts and minimize errors.

Promoting Responsible Consumption and Recycling

Promoting responsible consumption and recycling in sewing and quilting helps create a more sustainable community of crafters! By being conscious of how we use and dispose of materials, we can reduce waste and encourage others to do the same.

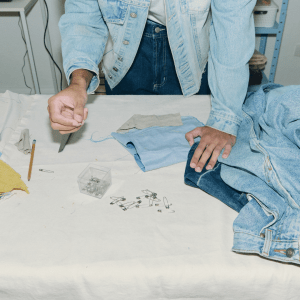

- Upcycling Projects:

- Give old garments a new life by upcycling them into new creations. Transform outdated clothes into stylish new pieces, helpful household items, or gifts for friends and family.

- Get inspired by online tutorials and communities that share creative upcycling ideas and techniques.

- Clothing Swaps and Donations:

- Participate in clothing swaps to exchange unwanted items with others. Swaps are a fun and sustainable way to refresh your wardrobe without buying new items!

- Donate unused fabrics and garments to charities or community groups, ensuring they find new homes and purposes.

- Repair and Mend:

- Repair and mending clothing and quilts can extend their life. Learning basic mending techniques like patching holes and replacing zippers can save your favorite pieces from ending up in the landfill.

- Invest in a small sewing kit to keep on hand for quick repairs and adjustments.

By adopting these sustainable sewing and quilting practices, you contribute to a healthier planet and create unique, high-quality pieces that tell a story. Every small step towards sustainability makes a significant impact!