Immersing ourselves in a new hobby may lead us to questions we never thought of asking! For example, at the heart of our beloved sewing and quilting projects lies fabric, the canvas upon which sewists and quilters weave their magic. But have you ever wondered about your fabric’s journey before it reaches your fingertips?

Here, we’ll cover the fascinating fabric creation process, where raw fibers transform into the vibrant materials that inspire our projects! Whether you’re a seasoned sewist or just starting, understanding this journey adds a new layer of fascination to your crafting experience.

Let’s Talk Fibers

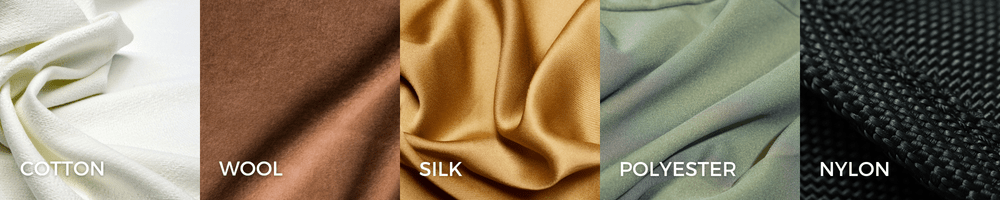

Natural fibers, such as cotton, wool, and silk, are sourced from plants or animals. Cotton cultivation occurs primarily in warm climates where mature cotton bolls are picked from the plants and then subjected to ginning. This process separates the fibers from the seeds and other impurities.

Wool is obtained through shearing sheep. It’s followed by cleaning the wool to remove dirt and grease, carding to align the fibers, and optional dyeing for coloration. Silk production involves rearing silkworms, harvesting their cocoons, boiling cocoons to soften the sericin coating, and then reeling the silk filaments to produce yarn.

Then, we have synthetic fibers like polyester and nylon, made from oil-based chemicals. Polyester is created by combining small molecules from petroleum, a process called polymerization. These combined molecules are then melted and pushed through tiny holes called spinnerets to form long strands of fibers.

Nylon goes through a similar process where specific chemicals derived from petroleum are mixed to form polymers, which are then pushed through spinnerets and cooled down to create nylon fibers. Essentially, polyester and nylon are made by melting oil-based ingredients and shaping them into fibers.

These processes highlight the contrasting methods of obtaining raw materials for natural and synthetic fibers, each contributing to the diverse range of products available in the textile industry!

Spinning

After the fibers are harvested from natural sources or synthesized from petrochemicals, the next step in the textile production process is spinning them into yarn! The spinning process involves aligning the fibers and twisting them together, forming a continuous thread. This process is crucial as it imparts strength and coherence to the yarn!

Several methods of spinning are employed in the industry. One method is ring spinning, a traditional technique for producing fine, strong yarn. The fibers are drawn out, twisted, and wound onto a bobbin in a ring spinning.

Another method is open-end spinning, a faster alternative that results in bulkier yarn. In open-end spinning, the fibers are fed into a rotor that rotates rapidly, pulling and twisting them together to form yarn. Each spinning method offers distinct advantages and is chosen based on the final yarn’s desired characteristics and the production efficiency required.

Dyeing

Dyeing is the next process in textile manufacturing, where color and patterns are infused into yarn or fabric. This step is versatile and can be carried out at different stages of production!

Fiber dyeing, also known as stock dyeing, is a method in which the fibers are dyed before being spun into yarn. This approach ensures uniform coloration throughout the yarn and fabric.

Yarn dyeing, in contrast, involves dyeing the yarn after it has been spun. It is commonly employed for creating patterned fabrics using different colored yarns.

Lastly, piece dyeing occurs after the fabric is woven or knit. In this method, the entire fabric piece is submerged in a dye bath, allowing for the uniform application of color.

Each dyeing method offers distinct advantages in color control, efficiency, and flexibility, catering to various requirements in the textile industry!

Weaving and Knitting

Following the dye production stage for yarn, the process advances to transforming yarn into fabric, achieved through either weaving or knitting techniques.

Weaving is a method that entails interlacing yarns at right angles to form a fabric. Basic weave patterns such as plain, twill, and satin are commonly utilized. Each imparts distinct characteristics to the resulting fabric, including texture, durability, and appearance. The chosen weave directly influences the fabric’s properties, like its drape, strength, and surface finish.

Knitting involves interloping yarns to create fabric. Knitted fabrics, like jerseys and rib knits, are known for their elasticity and stretchability, which distinguishes them from woven fabrics. The knitting process offers versatility in fabric design and texture and variations in stitch patterns, allowing for the creation of diverse fabric structures and surface effects.

Each technique—weaving and knitting—contributes to the spectrum of fabrics available in the textile industry, catering to various applications and consumer preferences.

Finishing

After the fabrication process through weaving or knitting, the next stage is the finishing process, which enhances the fabric’s appearance, texture, and longevity.

Mechanical finishes use techniques like brushing, which raises the fabric’s surface fibers for a softer feel and enhanced texture. Calendaring involves the application of heat and pressure to smooth the fabric’s surface, creating a fantastic sheen and improving the feel when you pass your hand on the fabric. Embossing creates decorative patterns or textures on the fabric’s surface, adding an excellent aesthetic appeal.

We also have chemical finishes, including treatments to boost the fabric’s functionality. These treatments include applications for water repellency, ensuring the fabric repels water and remains dry in wet conditions. They also have wrinkle-resistance treatments that minimize creasing and maintain the fabric’s smooth appearance. Chemical finishes may also include flame inhibitor treatments to enhance the fabric’s resistance to ignition and combustion, making it safer for wear.

Together, these finishing processes are crucial in refining the fabric’s characteristics, making it more visually appealing, comfortable, and functional for its intended use!

Cutting and Sewing

Once the fabric is finished, it is prepared for the final production stage: pattern making and assembly into textile products. This phase begins with pattern making, creating templates for the desired item. These patterns serve as guides for accurately cutting the fabric into individual pieces. The fabric is then carefully selected to meet the project’s specific requirements. This involves considering factors such as fabric type, weight, color, and pattern.

Once the fabric is chosen, it is distributed to local quilt and sewing shops, where it becomes available for purchase by creators like you! These shops are hubs for enthusiasts and professionals, providing various fabrics, notions, and tools for sewing and quilting projects.

Understanding the fabric creation process allows you to choose the best materials for your sewing and quilting projects. Each step, from harvesting raw materials to sending the final product to your favorite dealers, plays a crucial role in the quality and characteristics of the final fabric. The next time you start a project, take a moment to appreciate the journey your fabric has taken to reach your hands. Check out your nearest JUKI dealer and see the fabrics available here! Happy sewing and quilting!